The classic look of denim meets the freedom of all-direction stretch for elevated comfort. Made to move with you and keep its shape.

Shop For

Discover the classic styles and trending silhouettes to put on your radar

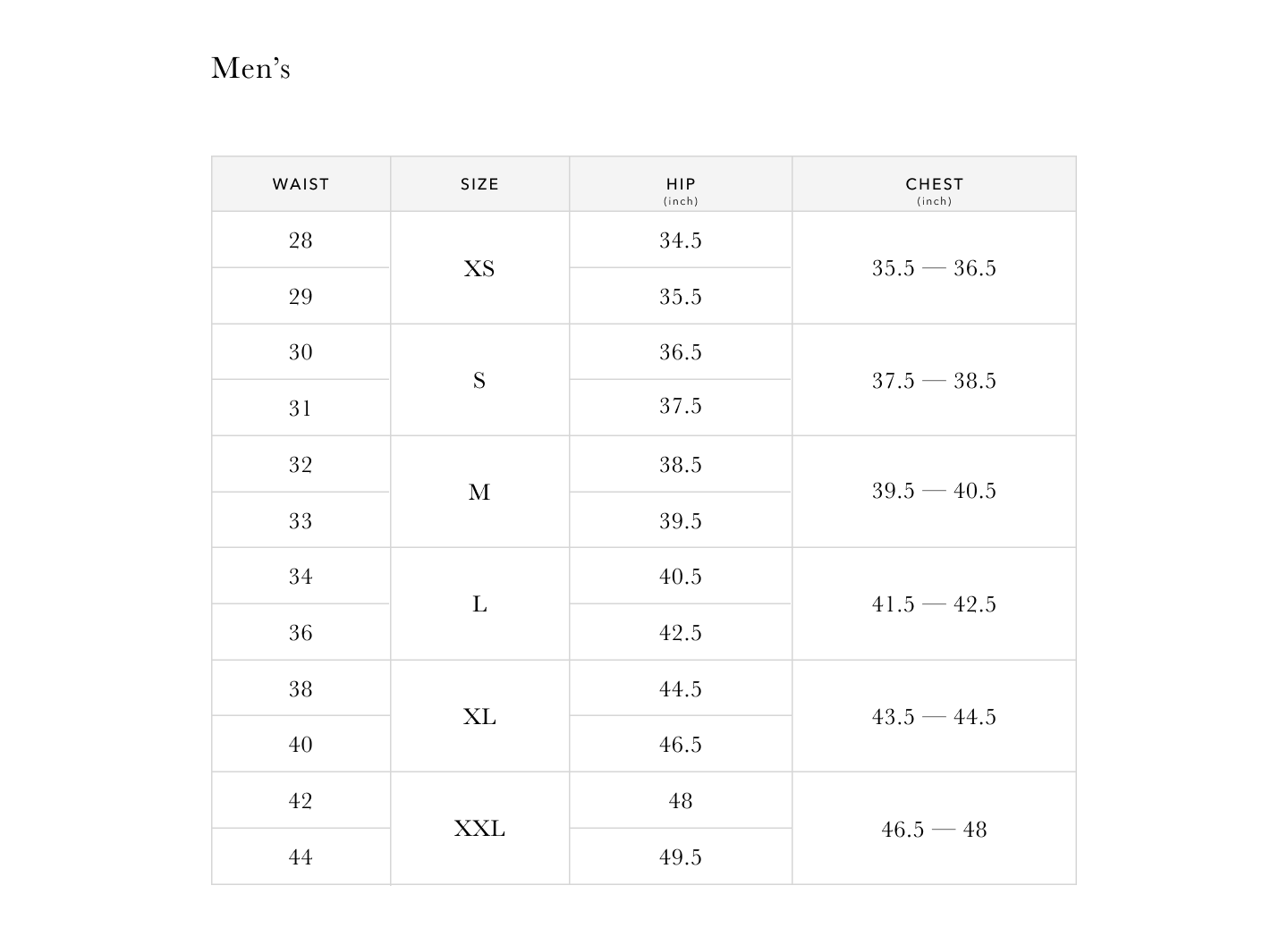

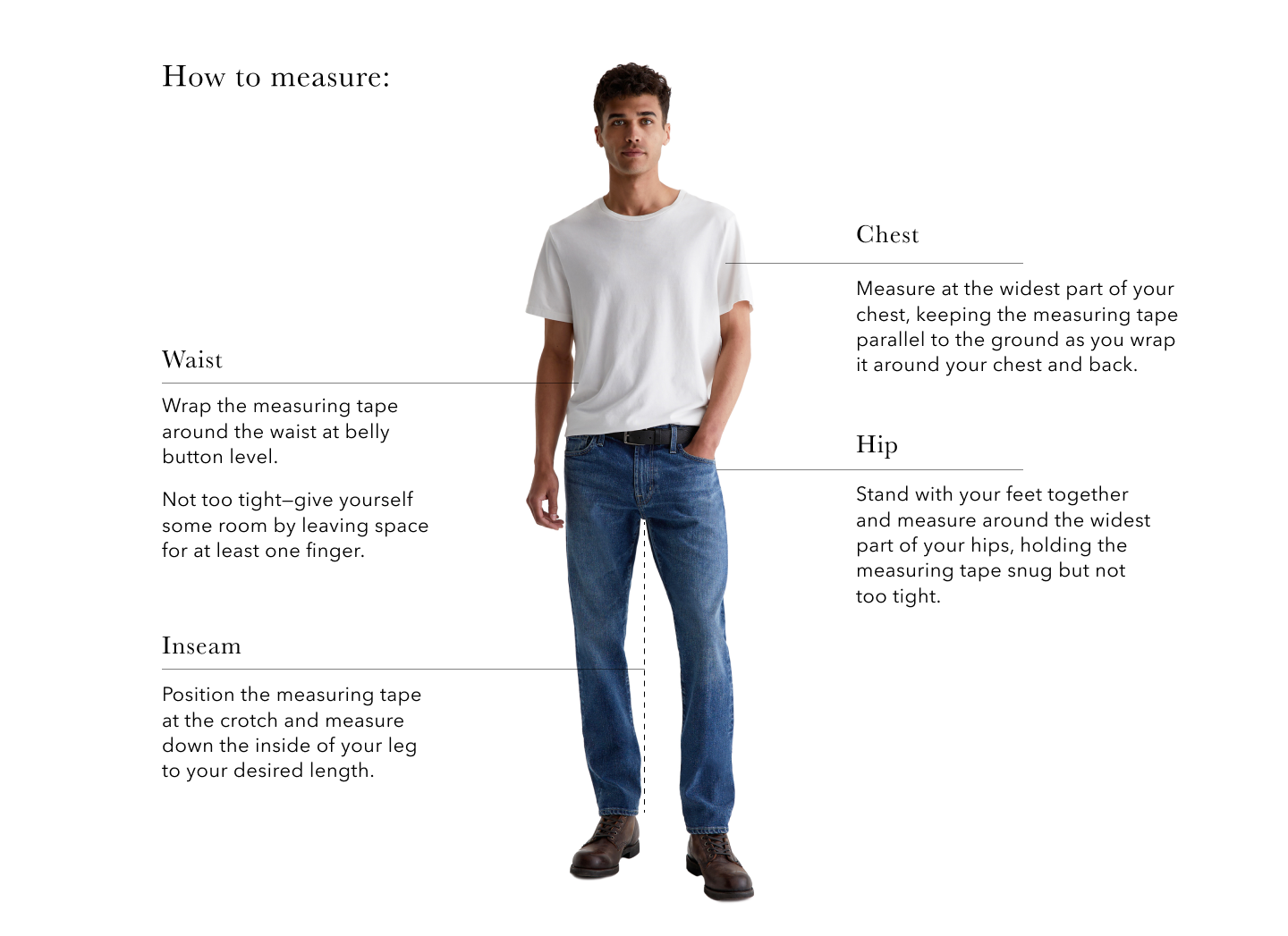

Check out our size chart and measurement guide for the best fit possible.

Expert fits. Premium fabrics. Essential washes.

We've perfected the formula for creating the denim you'll want to live in. Our designers take the time to get everything just right — all the way down to the smallest details. We use the best artisan fabrics from Japan and Italy, plus obsess over washes to recreate the lived-in look of the natural wear process.

It's all in the details. AG-ed™ Denim gets special one-on-one attention from our denim team to achieve the broken-in characteristics that come with years of wear—anywhere from 1 to over 20 years. The multi-step process involves distressing by hand, laser-fading, and expertly placed elements like honeycomb whiskering at the back knee.

We didn't invent denim—we simply perfected it.

The classic look of denim meets the freedom of all-direction stretch for elevated comfort. Made to move with you and keep its shape.

A special left-hand twill construction that allows the yarns to gently relax and untwist for a velvety-soft feel. Designed to get softer with every wear.

Polished, ultra-comfortable fabrics you'll want to collect in every color

A refined alternative to denim. Our best-selling Italian sateen featuring lightweight stretch construction with a soft, brushed texture.

Lightweight, moisture-wicking sateen with performance stretch for the man on the go. Comfortable and quick-drying to keep you cool and confident all day.

The best fits deserve the best fabrics. For our artisan fabrics, we choose mills with a deep commitment to the craft. That's led us to Italy for our Sueded Stretch Sateen (SUD) and the Kaihara, Kurabo, and Nihon mills in Japan for our selvage denim.

Selvage denim is made the old-school way—on traditional shuttle looms that yield narrower denim yardage and the clean "self-edge" finish that gives this fabric its name. We work with the best denim mills around the world to bring you selvage denim that honors the rich heritage of denim craftsmanship.